The IsoFlow™ Dispensers are integrated systems, which precisely dispenses liquid reagents in lines onto membranes for the production of immunochromatographic diagnostic test strips. IsoFlow™ accurately and repeatedly applies a continuous reagent line onto the solid medium.

IsoFlow™ uses digitally controlled positive displacement pumps in combination with precision nozzles to develop a uniform stream of reagent. The nozzles are moved over the membrane using a digitally controlled carriage resulting in a fine line of reagent on the membrane with an inherently uniform reagent density (uL/mm).

IsoFlow™ simplifies the development, optimization and manufacture of diagnostic test strips by allowing the operator to easily vary the dispense rate by entering the desired value (in uL/mm) into IsoFlow™'s hand-held terminal. There is no need to "recalibrate" between settings.

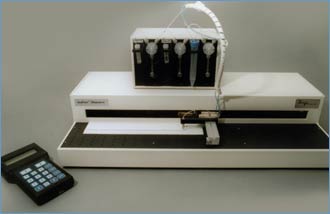

The original IsoFlow™ Flatbed Dispenser can typically produce 6,000 tests per hour. In the most popular configuration the test and control lines are dispensed with LCP nozzles while an atomizing nozzle simultaneously delivers the conjugate to the conjugate pad, as seen on the left.

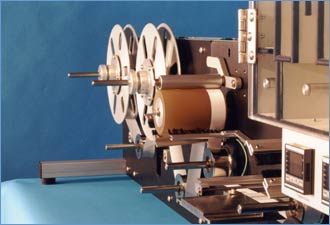

The IsoFlow™ Reel-to-Reel Dispenser can typically produce 35,000 tests per hour (more than 60,000 tests per hour is possible). Line spacing on the membrane is precisely controlled so test and control lines line up in the cassette.