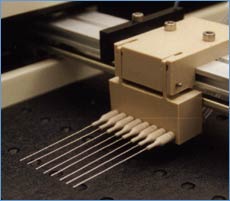

IsoFlow™ Low Contact Pressure (LCP) nozzles are used to deliver a fine line of reagent (typically antibodies) to the membrane. The IsoFlow™ Low Contact Pressure (LCP) nozzles allow for greater flexibility in operating parameters than non-contact type dispensers. Reagent delivery rates below 0.01 uL/mm are possible with carriage speeds from 10-300 mm/s. The nozzles typically have larger inside diameters (ID) than non-contact type nozzles. The large ID lowers shear stress on the fluid, allows lower dispense pressures and greatly reduces the chance of clogging.

The key to the LCP technology is the flexible nozzles. Variations in membrane thickness cause the nozzle to flex a little more or less so that contact with the membrane is always maintained. The contact pressure is so low that there is no significant mechanical stress on the membrane. A variety of nozzle geometries and materials are available.

The IsoFlow™ Atomizing nozzle is used when wide reagent lines are desired. It is primarily used to for dispensing conjugates onto polyester or fiberglass pads. The large inside diameter (250 mm) of the nozzle allows for low delivery pressures and shear while minimizing clogging. It is ideal for use with viscous reagents (high sugar concentrations). The Atomizing nozzle can be used with the LCP nozzles so that all reagents are dispensed in one pass. The Atomizing nozzle requires a clean compressed gas source (air or nitrogen) to create the aerosol. The nozzle requires approximately 2 SLPM (0.07 SCFM) of gas source at 15 to 20 PSI (1.0-1.3 bar).